Sublimate your surfaces

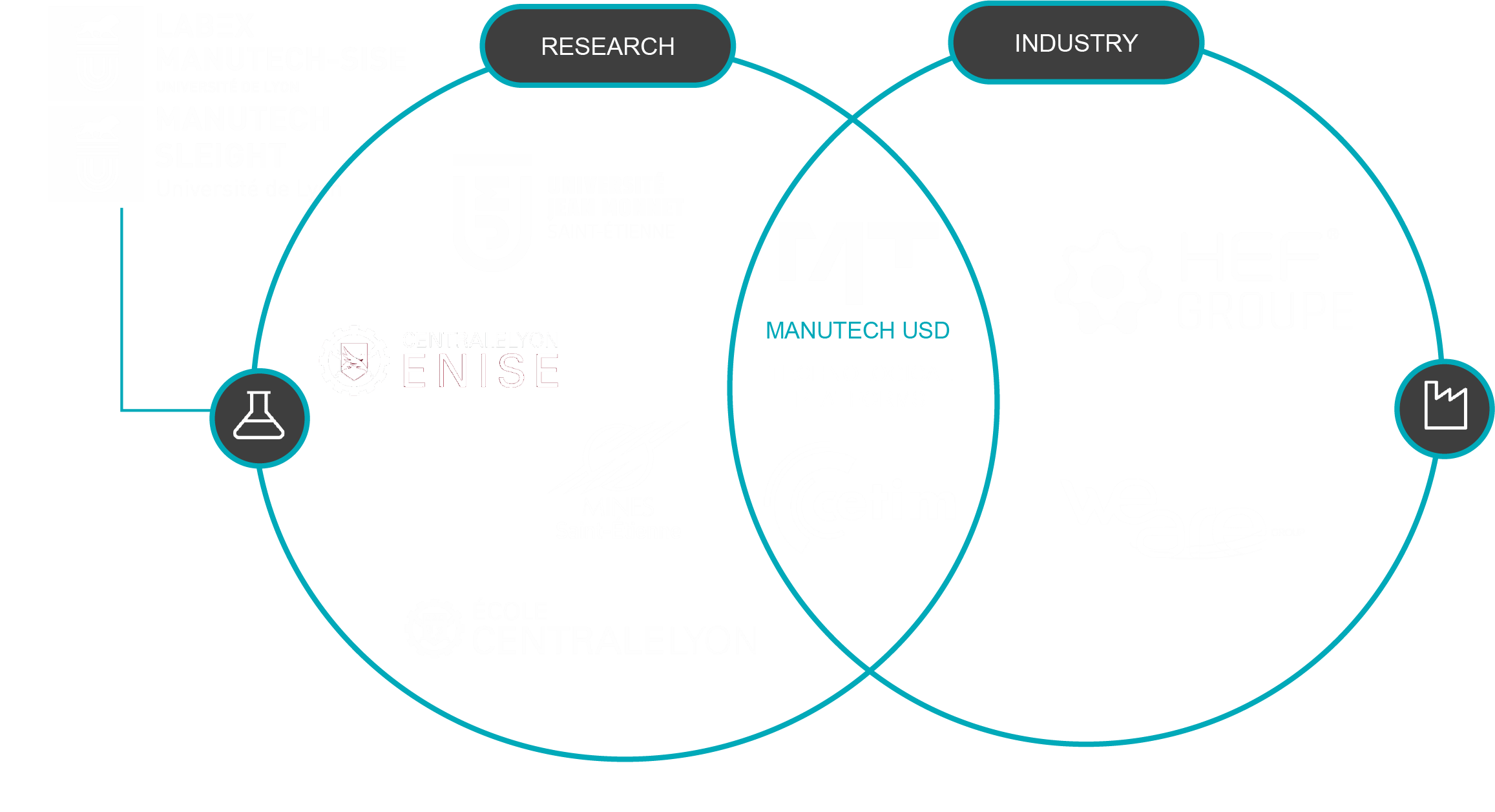

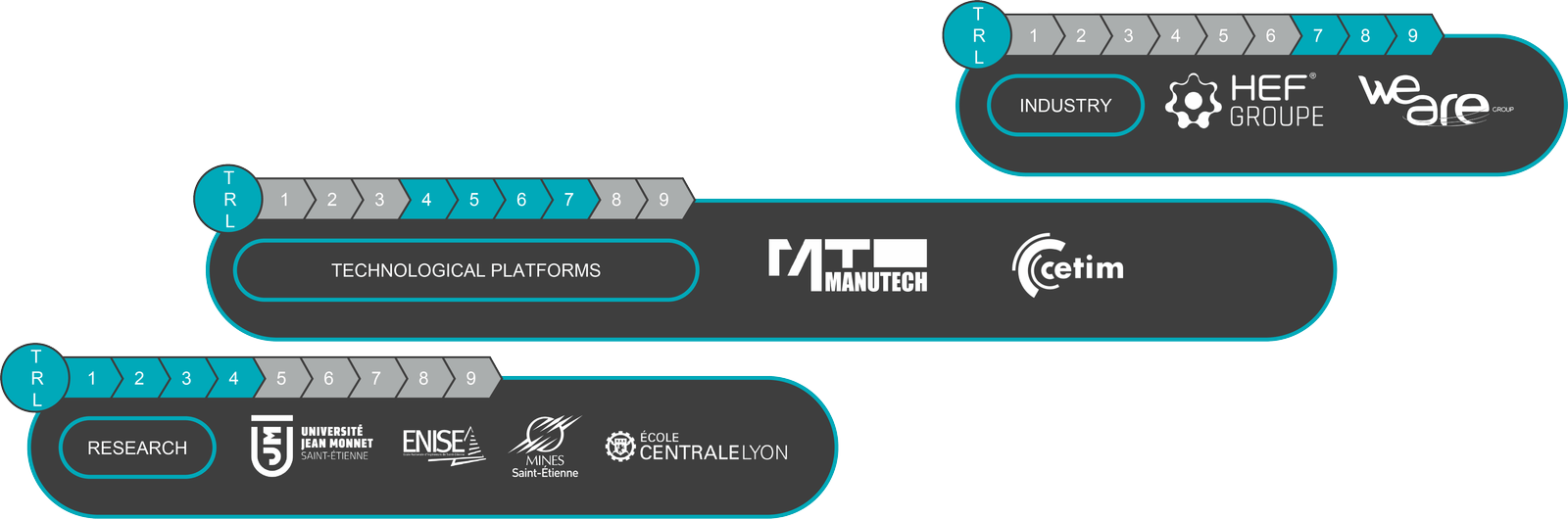

First European femtosecond platform for industrials

A breakthrough

technological

opportunity…

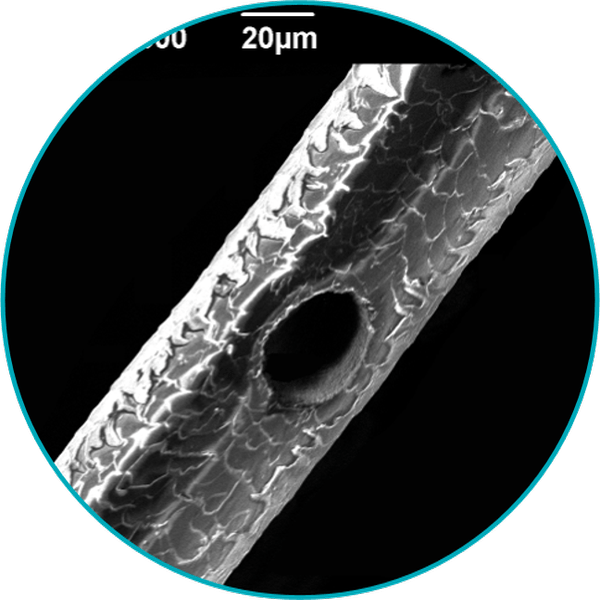

Femtosecond lasers (10-15s) generate a specific interaction between the photons and the targeted material resulting in an impact controlled sublimation: precise, reproducible and without unwanted heat diffusion effect.

The technology enables the cutting, engraving and functionalization of materials through an eco-friendly dry processing with low electrical consumption and no additional

chemicals required.

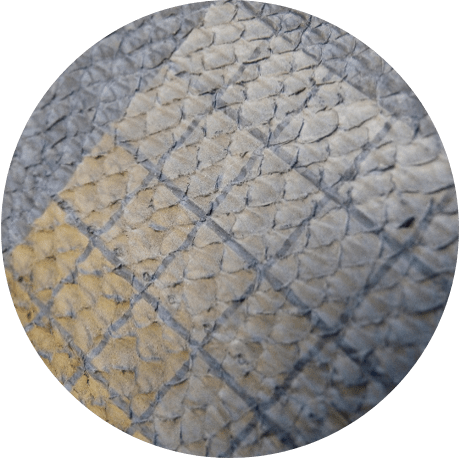

Engraving & marking

Engrave and mark the surface of a material with a topography controlled down to a nanometric precision. Marking is also possible within certain materials.

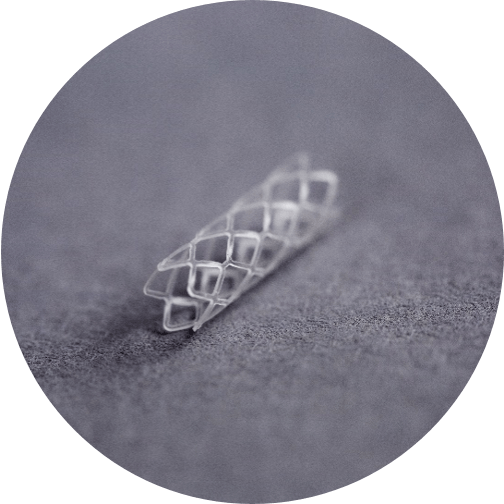

Cutting

Go through any material (wood, plastic, cardboard, metal…) with limited thermal impact and micrometric precision at high-processing speed.

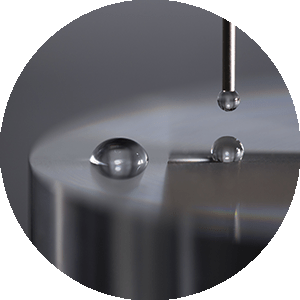

Surface functionalisation

Transform the properties of a material to give it new functionalities in order to improve its performances (adherence, friction, wettability, cellular growth, conductivity, waves trap…)

Femtosecond: an infinitesimal

unit of time…

In 100 femtoseconds, light doesn’t have the time to go through a hair.

The interaction time is inferior to the atoms vibration time.